Reactor Experiments

The design of the MIT Reactor (MITR) makes it ideal to conduct in-core experiments, with the possibility of running multiple long-term experiments simultaneously. The reactor provides an irradiation environment very similar to that of a full-sized light-water power reactor in a convenient compact area with good access for sampling and instrumentation (see below). This, along with long operating cycles and a large number of operating days each year, makes it ideal for the development and testing of materials, fuels and instrumentation suited to nuclear environments.

Vital Nuclear Engineering Research

The in-core research program at the MITR is an integral part of the Department of Energy’s effort to improve current generation nuclear reactors and develop new reactor technologies with improved economics and safety. It is the only university research reactor engaged in testing significant irradiation damage levels in environments representative of commercial power reactors, and is an excellent complement to national laboratory test reactors such as the Advanced Test Reactor (ATR) at Idaho National Laboratory (INL). Current irradiation experiments cover four major areas:

- Accident tolerant fuel development

Developing accident tolerant fuel became a focal point for the nuclear industry following the 2011 earthquake and tsunami that led to the Fukushima accident in Japan. This fuel would be able to withstand “beyond design basis” accidents without releasing radioactivity into the environment. The two major components of nuclear fuel are a uranium-bearing material surrounded by a “cladding” which acts as a barrier between the uranium and the reactor coolant water. At most commercial reactors, nuclear fuel cladding is currently made from a metallic alloy of zirconium called Zircaloy™. Ceramic composite material, however, is known for having better high temperature strength and corrosion resistance compared to Zircaloy™ and is being investigated as an alternate cladding. The NRL carried out the first-ever irradiation tests in high temperature, high pressure water of a ceramic composite material based on silicon carbide as an alternative to Zircaloy™. These early results demonstrated that testing materials in an irradiation environment is crucial to understanding their behavior and the program has played a major role in developing a viable ceramic composite cladding. Efforts are continuing with the MITR as a major irradiation test bed for an accident tolerant fuel program led by Westinghouse. Similar irradiation experiments have been undertaken at the MITR for a group at Oak Ridge National Laboratory, Ceramic Tubular Products LLC (a company founded by early developers of ceramic fuel clad concepts) and for researchers at MIT who are developing alternate cladding materials and improving the fundamental understanding of how these materials respond to irradiation.

- In-core instrumentation testing

The extreme in-core environment of a nuclear power reactor, or recreated environment in a research or test reactor, proves challenging for instrumentation. Instrumentation, such as sensors of various types, however, are vital to fully exploit expensive irradiation experiments in a reactor. They are used to characterize the test environment (temperature, pressure, radiation intensity and various chemical parameters) and to measure the response of the test materials in real time. The alternative to real time measurements is the periodic removal of samples for testing, which is expensive, time-consuming, may affect the parameters being measured and gives no information about the changes that occur between removals. Sensors capable of withstanding extreme nuclear environments also have applications in operating power reactors to monitor normal and accident conditions. The MITR has an ongoing program of in-core testing of advanced ultrasonic and fiber-optic sensors, as well as more traditional thermocouples optimized for nuclear use at high temperatures. In-core tests have also included detectors for neutron and gamma irradiation, measurements of electrochemical corrosion potential (an important parameter for understanding the corrosion and cracking of metals in water or molten salt coolants). A specialized sensor for measuring the crack growth in a stressed sample in-core was adapted from a European reactor and successfully demonstrated in the MITR.

- Fluoride salt-cooled High-temperature Reactor (FHR) research

The FHR is a promising new reactor design that would be efficient, safe and economical. In addition to generating electricity, it would also be able to operate at temperatures high enough to provide heat for industrial processes. Such reactors would also be much better suited for “load-following” (adjusting the output of the reactor to accommodate changes in the demand for electricity on the grid) than current power reactors. This would allow FHRs to work effectively as part of a hybrid electrical grid with significant power generation from variable solar and wind. The design is based on combining several technologies: the fuel from high temperature gas reactors, modern gas turbines for power production, and a molten lithium fluoride/beryllium fluoride salt (flibe) as the coolant. Many aspects of the technology have been previously tested, but many technical challenges remain to demonstrate a complete reactor. Understanding the behavior of the molten flibe salt and its interaction with the other reactor components under irradiation is vital. Four irradiations of flibe have been carried out at the MITR to advance the technologies needed for FHR development. These were the first irradiations of flibe since an experiment at Oak Ridge National Laboratory in the 1960s and ‘70s on a related reactor concept where the nuclear fuel is dissolved in the salt (FHRs use solid fuels). These irradiations contribute essential data to development efforts in both the United States and China (through a collaboration with the Chinese Academy of Sciences and the Shanghai Institute of Applied Physics).

- Nuclear fuel testing

Advances in nuclear fuel design to improve safety or efficiency require extensive testing to reach the point where they can be demonstrated and more widely adopted in operating power reactors. In the U.S., in-core testing of actual fuel materials was once only possible in test reactors at national labs, primarily the ATR at INL. In 2003 the MITR was licensed to test actual fuel materials in its core, allowing new fuel concepts to be tested on a small scale and at significantly reduced cost and shorter turnaround compared to larger scale experiments in the ATR. Two types of fuel samples have been tested. The first tested the impact of providing an additional coolant channel on the inside of a nuclear fuel rod to reduce the temperature of the fuel and improve safety. The second tested the response of a different form of uranium fuel, which is a better heat conductor than the fuel typically used in power reactors. The better conductivity reduces the temperature of the fuel and improves safety. It may also allow the fuel to operate longer in the reactor to more fully utilize the uranium it contains. Planning is currently underway to perform a third fuel experiment to obtain data in support of an advanced reactor concept being developed by TerraPower – a private company dedicated to innovative energy technologies.

Some basic characteristics of the in-core facilities that have been used at the MITR for this research are given below. For inquiries about specific in-core experiments or to explore possibilities for new experiments, please contact David Carpenter. Additional details about in-core experiments can be found in the MITR User’s Guide.

Facilities

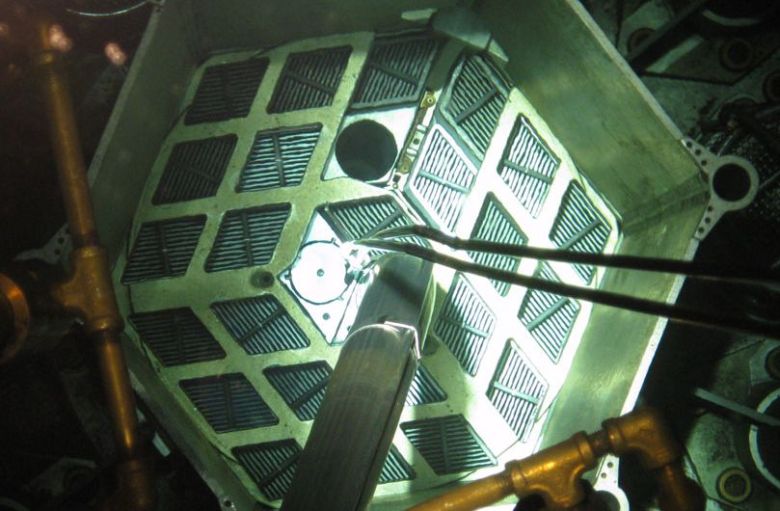

Of the 27 fuel element positions in the MITR, three are dedicated to in-core experiments. These positions offer the highest neutron and gamma fluxes available. Additional spaces in and around the core tank offer further flexibility. Details about the MITR’s in-core experimental facilities can be found here. While specific experiment designs are based on user requirements, there are two commonly-used facilities available:

- Pressurized water loop capable of mimicking the conditions of a pressurized water reactor or boiling water reactor core (up to 300°C and 10 MPa), and

- Inert gas facility able to irradiate up to 900°C, typically with a helium/neon mixture.

Both of these facilities can accept a variety of samples, including sealed capsules (e.g. for irradiation of reactive materials requiring controlled atmospheres). Examples of other recent in-core experimental facilities are:

- 1400°C high-temperature irradiation facility,

- Fueled irradiations with typical cladding and fuel centerline temperatures, and

- 700°C fluoride salt facility with capture of tritium and condensates.

Instrumentation and Control

Precise control, monitoring, and data acquisition are central to an experiment’s operations. One of the important advantages of the MITR over other reactors is the ability to instrument and actively monitor every experimental position. Each facility can monitor pressure, temperature, and chemistry parameters, in addition to the data acquisition needs of the experiment. Some examples of in-core sensors that have been used at the MITR are thermocouples, miniature neutron and gamma detectors, ultrasonic transducers, fiber-optic probes, potential-drop monitors, and ECP electrodes. Our staff works with users to determine the most suitable arrangement and composition of instrumentation for each project.