NRL and INL researchers test new radiation sensors at recently restarted TREAT facility

From left to right: NRL researchers Drs. Mike Ames, David Carpenter, and Kaichao Sun in the TREAT facility control room.

In June, MIT Nuclear Reactor Lab (NRL) researchers Drs. Mike Ames, David Carpenter, and Kaichao Sun traveled to the Transient Reactor Test (TREAT) facility at Idaho National Lab (INL) to test proposed upgrades to TREAT’s nuclear instrumentation. The MIT researchers worked alongside members of the INL High Temperature Test Lab (HTTL) instrumentation group: Ryan Fronk, Troy Unruh, and Kevin Tsai. TREAT is a nuclear reactor built in 1958 to test fuel components and materials to failure. It was placed in standby mode in 1994 and was refurbished and restarted in late 2017. This experiment was part of the TREAT integrated research project (IRP), with Dr. Lin-wen Hu as the MIT principal investigator collaborating with Oregon State University (lead) and the University of Michigan. TREAT’s testing capabilities are an essential part of the complete characterization of commercial power reactor fuel under a variety of conditions, and are therefore vital to the U.S. program to develop fuel that can withstand severe reactor accidents (accident-tolerant fuel).

Tests at TREAT require measuring fuel and reactor parameters, such as temperature, pressure, and power level, in order to know the limits of the fuel being tested. These tests can simulate conditions that might occur during severe reactor accidents, without affecting the TREAT facility itself. The parameters are collected by sensors, which need to be reliable when there is a sudden surge in operating power, and be useful over a broad range of neutron fluxes (how many neutrons are in a given area over a period of time).

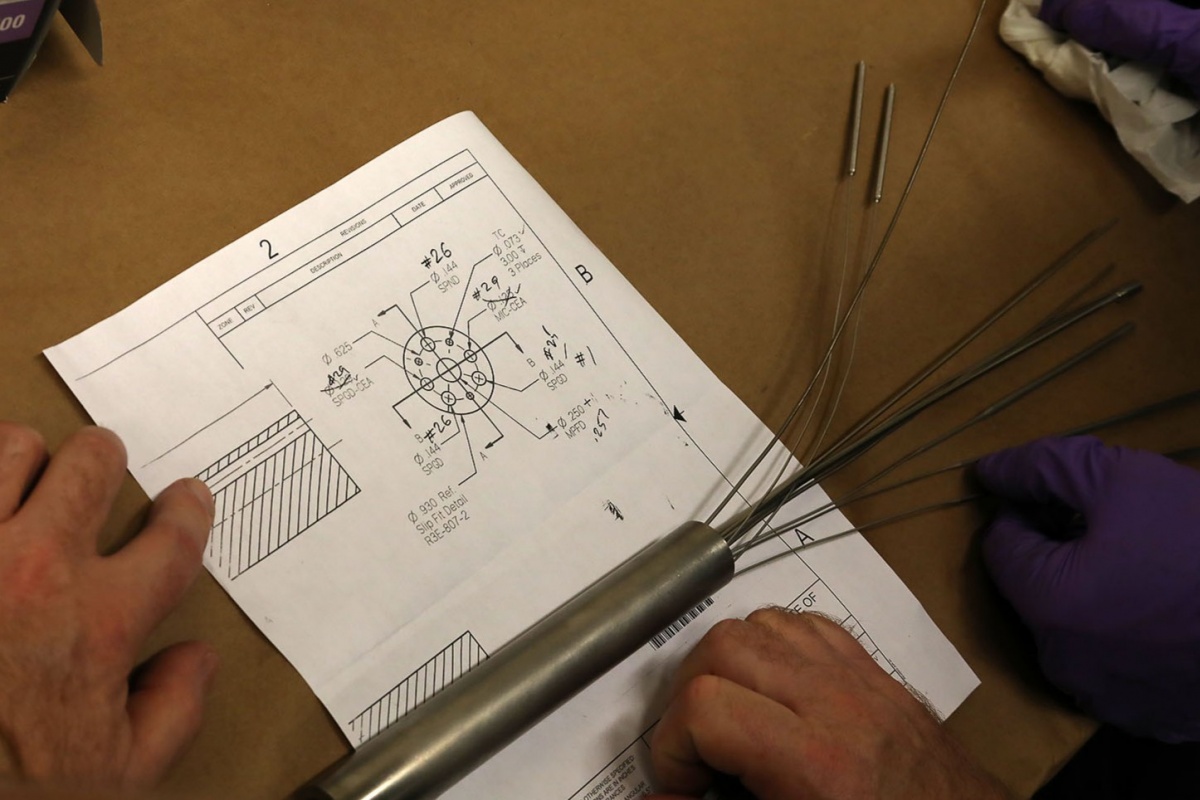

For the June tests, three different types of sensors were positioned in the TREAT core in the same area where test fuel materials are placed. Two types were commercially available self-powered sensors – one sensitive to neutrons and the other sensitive to gamma rays. These sensors are powered using the electrical current produced by the nuclear reactions taking place in the sensor itself, removing the need for an external power source. The third type of sensor, micro-pocket fission detectors (MPFD), is a new type of neutron sensor designed by INL and Kansas State University and is powered by a high voltage source.

The sensors were first tested in the MIT research reactor (MITR) at low power, then shipped to INL where they were tested at the TREAT facility at both similar constant and changing neutron and gamma intensities to observe how they responded. Once data at conditions comparable to the MITR tests was collected, the sensors underwent brief, intense power pulses ranging from 1,200 to 25,000 MW – utilizing the full capability of the TREAT facility and exercising the sensors at higher neutron intensities and changes in operating power levels.

The sensor’s responses were benchmarked using a set of passive neutron exposure monitors in removable capsules positioned next to the sensors for three of the TREAT tests. The passive monitors become radioactive when exposed to neutrons. To determine how many neutrons the sensors were exposed to, the radioactivity of the passive monitors was measured at INL’s gamma spectroscopy lab and then at the NRL. This data, in addition to what was collected by the sensors, will provide a comprehensive look at the sensor’s overall neutron exposure.

At the conclusion of the planned TREAT experiments, each sensor operated as expected, and their use was extended by the TREAT researchers for additional testing. The types of sensors used in this research will eventually be considered for installation at the TREAT facility to monitor the reactor and its future experiments for developing accident-tolerant fuel.