Back to the future: Researchers at MIT's Nuclear Reactor Lab help revive a salt-based nuclear energy technology abandoned decades ago

Left for dead in the 1970s, the molten-salt-cooled nuclear reactor has come roaring back to life—with the help of MIT. With its promise of improved safety, higher temperature electricity generation, and compatibility with a national grid increasingly fueled by sun and wind, the molten salt reactor concept is now attracting federal R&D money and sparking startups. Incorporating regulation-friendly technologies, it's also a reactor design on a fast track: One enterprise, Kairos Power, aims for a demonstration plant before 2030 and largescale commercialization soon after.

"As far as next generation reactor technology, this is probably the one closest to being realized," says David Carpenter SM '06, PhD '10, head of irradiation engineering at the MIT Nuclear Reactor Laboratory (NRL). "The idea is innovative but not farfetched, and it's not something that will require 30 more years of research."

Fulfilling this vision nevertheless requires overcoming technical obstacles—the kind of challenges for which the NRL, with its irradiation facilities and engineering expertise, is uniquely suited. Drawn by MIT's singular assets, the Department of Energy engaged the NRL in 2011 to lead a university consortium in a multiyear initiative to advance molten salt reactor design. The DOE funding enabled MIT, through a succession of studies, to deploy its nuclear reactor (MITR) and related testing apparatus as a proving ground for the materials and processes critical to molten-salt-cooled reactors.

"Nuclear engineering is notorious for making paper reactors, but this one is a step closer to reality because we are able to do experiments with materials we really want to use in molten-salt-cooled reactors," notes Carpenter, part of the team engineering the MITR molten salt studies. "We are building demonstration devices and getting real data."

"In fact, MITR, with its high neutron flux irradiation capabilities, is really the ideal place to conduct these scoping experiments," says Lin-Wen Hu SM '93, PhD '96, director for research and services at the NRL. "We may be small, but we can conduct first-of-its-kind experiments with shorter turnaround time than national lab reactors."

A quartet of studies

The research pursued by Hu, Carpenter and a team of MIT scientists and students over four distinct studies in the past nine years focused on testing aspects of the FHR molten salt-cooled high-temperature reactor, one of the two primary competing designs. In the FHR, billiard-ball-sized fuel pebbles float within a circulating flow of molten salt—a special blend of lithium fluoride and beryllium fluoride called flibe. This salt constantly absorbs and distributes the intense heat produced by the fuel's fission reactions.

"Salt reactors run at 600-700°C and atmospheric pressures, so you don't have to worry about containment problems, coolant vaporizing, or accidents involving melting fuel, as you might with pressurized water-based nuclear reactors," notes Hu. These are distinct advantages for this design in a tough regulatory environment.

The advantages of such a system were recognized decades ago, when the US government was determining the best path for the nation's commercial energy program. In the 1960s, Oak Ridge National Laboratory conducted tests on molten-salt-cooled reactors, "but the US decided to focus exclusively on light water reactor technology, which was favored by the Navy for its nuclear propulsion," says Hu.

In spite of its promise, the alternative salt reactor technology was abandoned.

Then a decade ago, "it sprang back to life," says Carpenter. "Since molten salt reactors were last investigated, many new materials and technologies have appeared, which make it possible finally to move this type of reactor design forward."

The new molten salt studies picked up where Oak Ridge left off. University consortium members analyzed experimental set-ups and results from the '60s and interviewed retired researchers to identify challenges that emerged during that period.

Two key feasibility issues drew their attention, says Carpenter. One involved the corrosive effects of salt on reactor materials, and tritium, a radioactive gas released from the salt at high temperature, which can diffuse through metal walls.

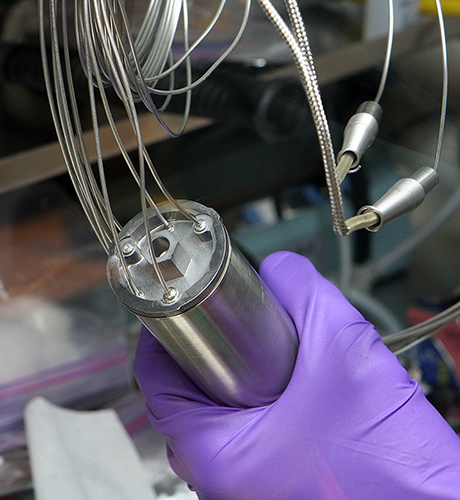

FS-1 Capsule Pre-Irradiation

Seeking solutions for salt and tritium

The experiments at MITR were fashioned to tackle both these feasibility questions. The MIT research team had a lucky break at the start. They were able to secure the original clean flibe salt from Oak Ridge National Laboratory that had been sitting in drums for half a century. Their first fluoride salt irradiation study (FS-1) subjected this flibe—purified by University of Wisconsin collaborators—to 1000 hours at 700ºC in the MITR core. The team also irradiated little discs of metal and ceramic samples that are known to resist salt corrosion at high temperatures.

"When we turned the reactor on, it felt like a historic moment, because the salt hadn't seen any neutrons since the 1960s, and we were holding our breath, wondering if we would find something unexpected," says Hu.

"We jumped right in aggressively with integrated tests, aiming to demonstrate we could do it, expose materials to corrosion, and look at tritium transport," says Carpenter, who created customized experimental and analytic apparatus for each study. "This first experiment gave us confidence we were on the right track: the materials didn't dissolve, and we measured tritium generated and transported through the irradiation."

FS-2, in 2014, added additional sample materials, in a larger two capsule design. The experiment produced one unexpected result. "We found that after the reactor shut down, as temperatures decreased, gamma radiation produced by fission products reacted badly with the salt," says Hu. "It turns out salt is prone to chemical reactions below 200ºC."

The team realized it needed to prevent salt from getting too cold, which meant sustaining temperatures higher than 200ºC. They determined that by deploying an electric heater uniquely outfitted for the extreme in-core conditions, they could maintain the salt hot, and reduce the likelihood of destructive chemical reactions.

The third experiment, begun in 2016, uncovered the substantial potential for tritium build up and chemical reactions on the walls of the steel gas tubing in the circulation system. The study also investigated different materials for the reactor that might help prevent excessive tritium release.

The study also investigated different materials for the reactor that might help prevent excessive tritium release. Different types of graphite were shown to have different tritium absorption behavior. Consequently, Hu says, "The outcome of this experiment should have a direct impact on FHR design."

FS-4, conducted in 2018, looked at materials that might prevent tritium from permeating the metal tubing through which flibe flows—tubing that might be used around the reactor core and in heat exchangers. The experiment demonstrated that aluminum oxide coating reduced tritium permeation by more than 90%.

The problems of tritium release and salt corrosion are not insoluble, suggest MITR researchers. "Our testing of a range of metal and ceramics composite materials shows we're on the right track to deal with corrosion," says Carpenter. "And the tritium issue does not seem insurmountable with additional research."

Big projects like this rely on a phased approach and iterative process. "Like Apollo, people don't go to the moon the very first time; they run mission after mission, conducting the kind of incremental experiments we do," says Hu.

New studies to resolve these questions, propelled by Kairos Power’s funding support, are already on the drawing board. And the MITR team, with its hands-on expertise, engineering know-how, and large community of scientists and committed students, is not only ready to deploy new experiments and beyond, but essential to the advance of the molten-salt-cooled reactor.

"We're best suited to design and execute reactor-based experiments, and learn from it," says Hu. "Together with national laboratories and consortium partners, we can help the nuclear industry develop reactor technologies that benefit from our experiment findings, and bring the first MSR to the marketplace.

Monitoring FS-4 Irradiation