Oak Ridge National Laboratory (ORNL) and Analysis and Measurement Services Corporation (AMS) recently completed testing of sensors for small light-water reactor systems. The performance data will be shared with U.S. nuclear companies to improve sensor instrumentation for advanced light-water small modular reactors (SMRs).

The data could also be leveraged to support other advanced reactor types cooled by gas, liquid metal or molten salt.

Looping Performance Tests

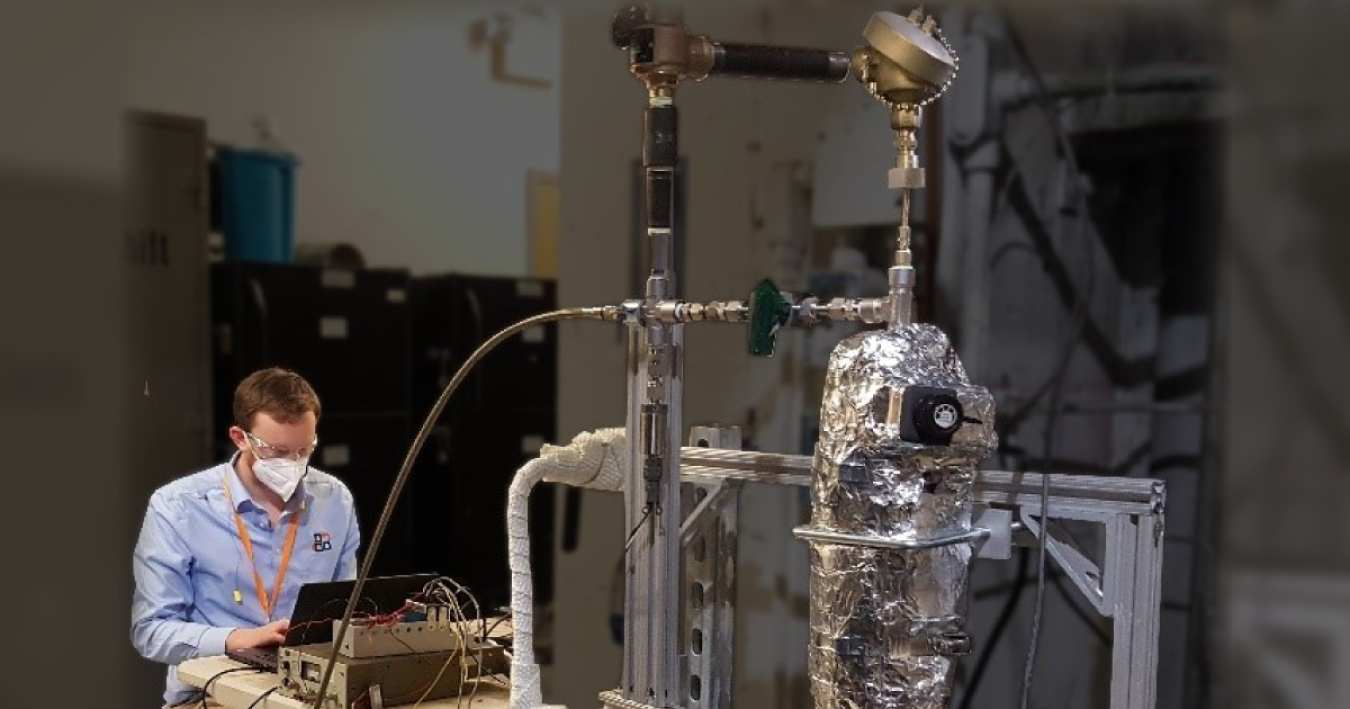

ORNL successfully tested nuclear-grade resistance temperature detectors (RTDs) using a thermosyphon test loop and a specialized steam loop constructed specifically for the project. The rugged temperature sensors were examined at the expected operating conditions of an advanced SMR that uses natural water circulation to cool the reactor.

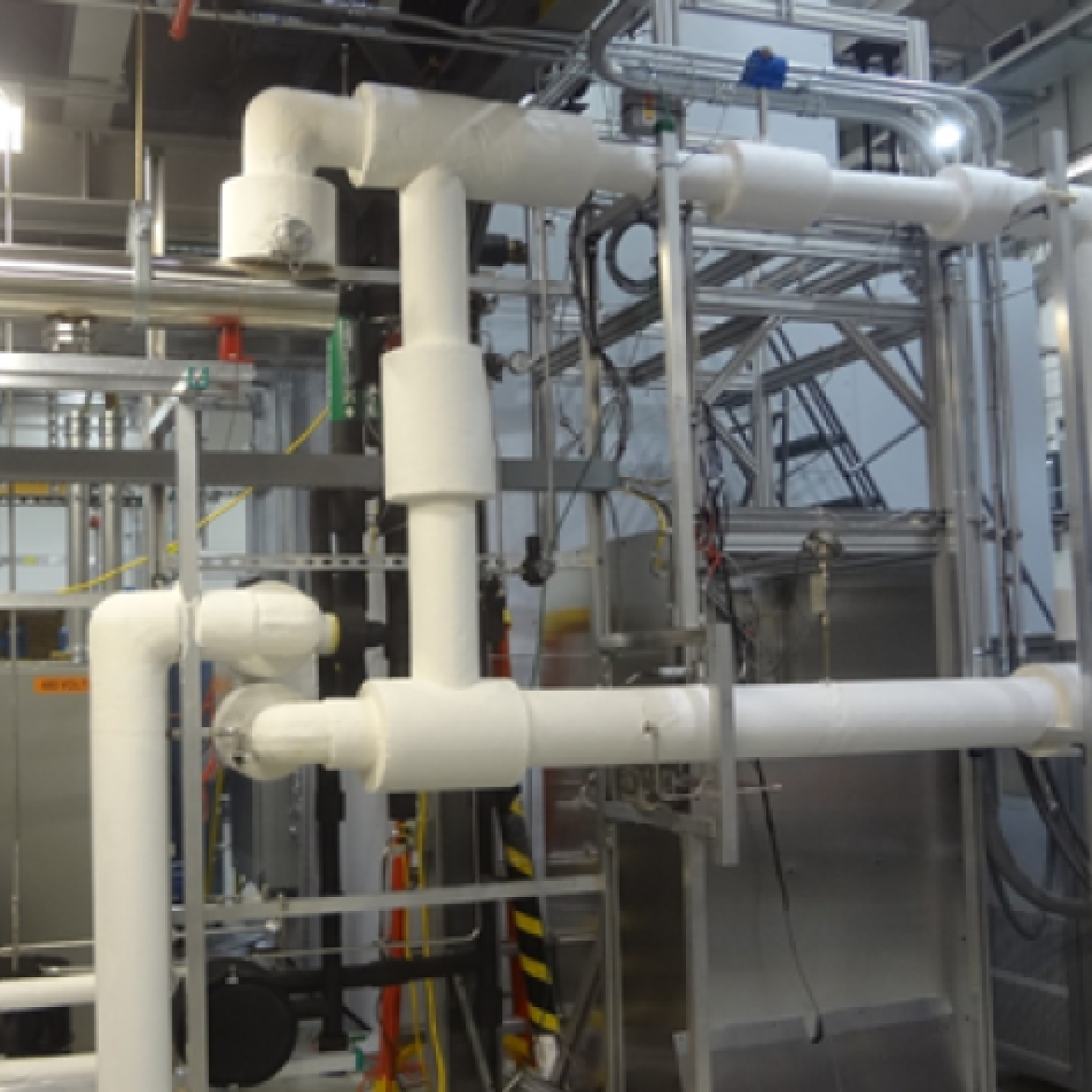

Water loop with the RTD sensor installed.

Researchers also assessed the sensor response time needed to detect changes in the coolant conditions that would require the reactor to safely shut down.

“Because the signals involved are used to initiate a safe shutdown of the reactor during an incident, validation of the instruments’ ability to perform is subject to strict regulatory scrutiny,” said nuclear engineer Nesrin Ozgan Cetiner, lead researcher for the project at ORNL who is currently a irradiation scientist at MIT. “Our research results will help guide industry partners in the selection of nuclear-grade RTDs suitable for safety-related temperature measurements of the reactor coolant and main steam of small modular reactors.”

Industry Benefits

The project was supported by the U.S. Department of Energy’s Gateway for Accelerated Innovation in Nuclear (GAIN), which makes government research facilities more accessible to the nuclear community in support of the commercialization of innovative nuclear technologies.

“GAIN has helped AMS greatly benefit from the resources and expertise at ORNL to test the performance of sensors and cables for the next generation of nuclear reactors, said Alexander H. Hashemian, a senior research engineer for AMS.

One of the motivations for the awarded GAIN Voucher was to characterize sensor performance in conditions relevant to NuScale Power and other natural circulation SMRs, such as Holtec’s SMR-160.

“Ultimately our goal is to help DOE’s Office of Nuclear Energy in its mission of helping the nation create a new generation of reactor technology,” Cetiner said. “The commercial companies who will build the reactors and manufacture the equipment need our research insights to ensure that these instruments perform as intended.”

ORNL and AMS are finalizing their findings and are preparing guidance to share with industry partners.

Learn more about our GAIN initiative.